HAPUMA’S PRODUCTION CAPACITY

1. GENERAL CAPABILITIES

HAPUMA – Comprehensive Strength in the Pump Industry

HAPUMA delivers a fully integrated production and service chain – from consulting, design, manufacturing, testing and installation to maintenance and repair – all operating under internationally certified quality and environmental management systems (ISO 9001:2015 and ISO 14001:2015).

Our R&D Center, equipped with advanced design software, state-of-the-art testing facilities and a team of highly qualified engineers, accelerates product development while enhancing performance and quality. All pumps are designed in full compliance with international standards such as ISO, EU and ANSI.

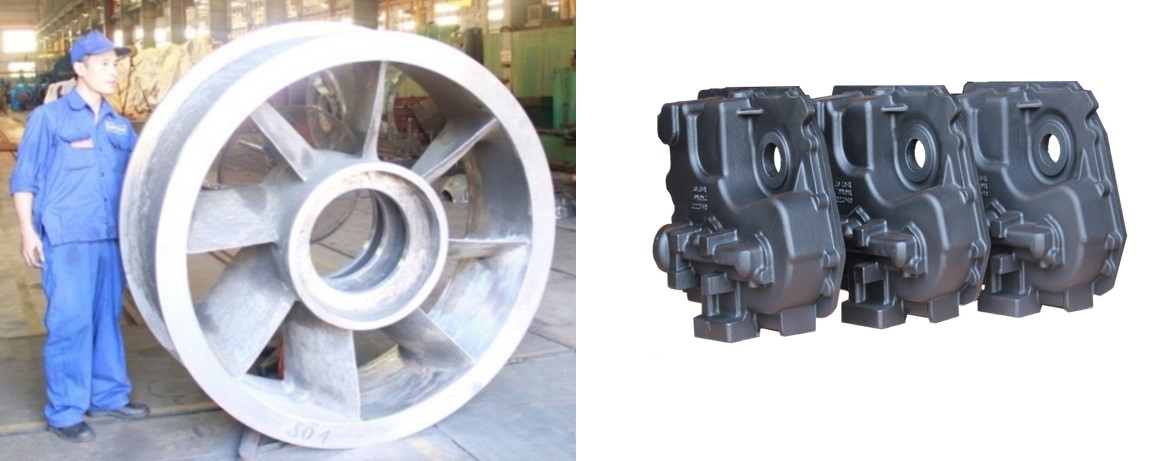

With a foundry capacity of over 3,000 tons per year, HAPUMA can produce cast iron components up to 10,000 kg and steel components up to 2,000 kg, meeting the most demanding technical requirements. Our castings have been successfully exported to the United States, Japan and South Korea.

Our machining facilities feature modern CNC systems capable of processing components up to 4 meters in diameter and 7.5 meters in length. All rotating parts are dynamically balanced in accordance with ISO 1940-01 standards.

HAPUMA also operates the region’s largest fully automated pump testing center, capable of testing pumps with flow rates up to 50,000 m³/h, heads up to 1,000 m and power ratings up to 2,000 kW. All test data is processed and reported using software compliant with ISO 9906.

With over 65 years of experience and a dedicated team of engineers and technicians, HAPUMA has established itself as a trusted partner in consulting, supplying and installing pumps and integrated systems – providing reliable alternatives to imported equipment and contributing to the global value chain.

2. FOUNDRY AND METALLURGY CAPABILITIES

HAPUMA operates a state-of-the-art foundry line with an annual capacity of over 3,000 tons, covering nearly 6,000 m² of workshop space. The facility is equipped with advanced technology and staffed by a team of highly skilled engineers and technicians.

We specialize in manufacturing large, high-precision castings from a wide range of materials – including gray iron, ductile iron, high-chromium wear-resistant cast iron, alloy steels, austenitic stainless steels and duplex stainless steels – all produced in compliance with international standards such as JIS, ASTM and ISO.

Key Features:

- Casting technology designed with specialized Cast Design software

- Advanced resin sand molding and patterning for exceptional precision

- Large-capacity medium-frequency furnaces and modern heat treatment systems

- Fully equipped shot blasting, finishing, testing and measurement facilities

- Proven capability in delivering large, high-quality castings across diverse materials

Photo: Foundry No. 1, covering an area of over 4,000 m².

2.1 Design of casting technology

Design, simulate and optimize casting technology using Cast Designer software, minimize damaged goods, improve casting quality and accuracy.

2.2 Manufacturing samples with advanced technologies

Depending on the requirements for accuracy, size and casting material, casting models are made with many different suitable technologies such as: 3D plastic printing, manufacturing precise wood or foam models and machining metal models. by CNC machine…

Print models with 3D printers. Manufacture accurate wood models

Manufacture accurate wood models. Manufacture digital models

2.3 Plastic sand mold technology

Furan and Alphaset plastic sand molds have high durability and good air release, allowing for casting large details with high precision and quality.

Mold making space and sand regeneration system

2.4 Medium frequency electric furnace system

Medium-frequency electric furnace system with a total capacity of 10 tons/batch and advanced annealing equipment and pouring barrels allow for smelting and casting of large parts.

2.5 Heat treatment of castings increases the mechanical strength and physical and chemical properties of the material

The heating furnace with precise heat control devices along with experienced engineers and skilled workers has increased the quality of castings and increased the physical and chemical durability of the material.

Heat treatment furnace with control device

2.6 Clean and finish castings

Casting parts are cleaned using shot blasting technology before being painted for protection using a semi-automatic line.

Blasting cleaning equipment 10 tons/batch

2.7 Testing equipment, process measurement and casting quality:

In each stage of technology, there are accurate testing and testing equipment and casting quality inspection equipment with high reliability.

Check metal composition Check metal temperature before pouring

Checking the mechanical properties of casting materials Checking the metal crystal structure

Check size and profile with a 3D scanner using specialized inspection software

2.8 Some typical molded products

Stainless steel casting products Gray cast iron casting products exported to Japan

High chromium alloy, wear-resistant cast iron casting products Duplex stainless steel casting products

2.9 Production of Molded Products

In addition to pump components, HAPUMA produces cast metal parts for the machinery and construction industries. Our molded products are recognized for their durability, precision and reliability, crafted from a wide range of materials and manufactured in full compliance with international standards.

By choosing HAPUMA, customers receive superior castings and the assurance of working with a trusted manufacturer backed by decades of expertise.

Tiếng Việt

Tiếng Việt